Why Water jet Cutting?

Abrasive water jet cutting (AWJC) technology is a very simple, environmentally friendly technology and therefore it becomes an alternative to other methods. AWJ has proved to be a fascinating manufacturing process due to its specific advantages when machining almost all engineering materials.

How to decide if waterjet cutting is the right process for your part?

There is a very simple methodology.At ALIND,we advice customers to opt for waterjet cutting, when the other cutting processes in the order, Flame cutting,Plasma cutting,Laser cutting,milling,wire cutting fail to produce their parts.

It is that simple to decide for opting to waterjet cutting process for your parts.For more detailed comparison, kindly give your time to read further…

When deciding on which option to use for your parts production process,consulting with an expert is often the best course of action; but you can also read below to understand the differences between each technique, and the advantages and disadvantages they have to offer .

How Water jet Cutting differs from other Profile cutting?

Laser,Plasma and Flame cutting are heat cutting processes.Wheras,Abrasive waterjet cutting is essentially a cold cutting process. Cold cutting means that there is almost no heat generated on the part being cut.

- Can cut up to 150 mm thick on any metal and up to 250mm thick in non metals

- Tolerance: +/-0.1 to 0.3 mm depending on thickness and length of part

- Unlike flame/plasma/laser cutting process there is no heat affected zones (HAZ)

- No warping during cutting process, hence long length to width ratio and frail parts can be cut

- No fatigue zones, no thermal distortion or degradation in physical properties of materials

- No discoloration and offers edge finish similar to sand blast finish

- No heavy burrs are produced. Often, parts can be used directly without de-burring

- No chatter, even brittle materials and heat treated, hardened steel can be cut

- No long lead time tooling and no need for costly fixtures.

- Scrap produced has a higher value and fully re-usable as there is no dross or slag

- Tight Nested layouts of shapes, with minimal kerf width of less than 2mm, offer great productivity

When comparing with Lasers

- Abrasive waterjets can cut many materials that lasers cannot.

- Laser cutting cause thermal distortion and hardening of the material at cut edges.

- Lasers cannot cut materials other than SS,MS.

- Lasers cannot cut materials higher than 10mm.

When comparing with Plasma and Flame cutting

- Abrasive waterjets can cut higher thickness than plasma cutting.

- Abrasive waterjets can cut what plasma cutting cannot cut.

- No work-hardening of edges, no HAZ and no micro cracks

- Edges are left perfectly clean with much nicer edge finish

- Abrasive waterjets are precise, needs no for further machining or labour-intensive finishing.

- Profiles can be much more closely nested, hence more parts per sheet

- Flame cutting a part needs time consuming finishing operation.

When Comparing with EDM

- EDM is extremely accurate, but very slow. It also requires an electronically conducive material

- Abrasive jets are capable cutting wider variety of materials including Non conducting materials

- Abrasive waterjets make their own pierce holes and much faster than Wire EDM

- EDM cannot take full advantage of closely nesting your part in full sheets.

- Abrasive waterjets require less setup and can cut bigger parts

When comparing with miling

- There is no extensive cutting tools required.

- No long Setup time and no fixture Cost.

- Abrasive waterjets cut a part with one pass.

- Machine virtually any material, including brittle and pre hardened materials,otherwise difficult materials such as Titanium, Hastalloy, Inconel, SS 304, tool steel etc.,

- Milling cannot take full advantage of closely nesting your part in full sheets.

- The scrap is usually more valuable in solid form than chip form.Waterjet cutting do not reduce all the metal to chip form.

- Waterjet cutting can be used for complimenting or replacing milling operations.

- Waterjet cutting can be used for roughing out parts prior to milling to take advantage of nested cutting layout.

When comparing with Punch Press

- Waterjet cutting makes lower cost per piece for short runs and fast turn-around from concept to production, no tooling cost and time.

- Abrasive jets offer more nesting possibilities ,hence more parts per sheet

Waterjet Cutting Methodology

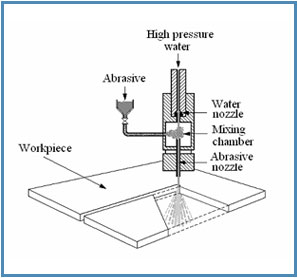

Most abrasive waterjet cutting theories explain abrasive waterjet cutting as a form of accelerated micro erosion. High pressure water at 3800 bar is passed thru a tiny orifice at a speed of approx.900 m/s – nearly three

times the speed of sound. The result is a coherent very thin extremely high velocity waterjet with a diameter of approx. 0.08 to 0.50 mm. Natural garnet sand particles are made to be sucked into the stream of the coherent waterjet and directed to hit the work piece on the cutting line with the very high velocity. There by hardest of metals and non metals can be cut or machined by micro erosion. Automating the process with programmable systems in conjunction with the CNC control provides precision and high flexibility with a wide variety of part profiles.

Thus, Abrasive jet cutting systems are considered as an efficient tool to cut work pieces which are previously considered "unmachineable" by conventional cutting methods.

Productivity of adopting to Waterjet cutting in your process

There is significant amount of material savings in waterjet cutting over conventional machining process. The abrasive stream produces minimal kerf width of 1 to 2mm, permitting tight nesting of parts. Your "scrap" metal is easier to re-use or recycle as there is no heat affected zone. Also, we use advanced nesting software to minimize material wastage. Hence you can have more parts per sheet.